Our Portfolio

Explore our completed projects and Unit facilities across locations.

Stainless Steel pump casing

Hydro Turbine

SS 316 Air Cooler undergoing aluminium oxide blasting for surface treatment

Precision-machined turbine casing set for power generation equipment

High-precision nuclear pump component for critical infrastructure

MRSAM Missile jet deflector components with advanced surface finishing

Heavy-duty generator base frame with intricate machining details

Industrial filter press system with precision-engineered components

Stator frame for large-scale electrical machinery

Steam turbine casing with complex geometric machining

ASME-certified pressure vessel with advanced welding techniques

Precision-machined rotor hub for industrial rotating equipment

Electrical control panel with intricate wiring and component layout

Specialized coal pulverizer component for power generation

Missile system component with high-precision surface treatment

Industrial decanter centrifuge component

Boiler pump assembly with complex machining requirements

Base frame for heavy industrial machinery

Stainless Steel Impeller

Follower component for precision machinery

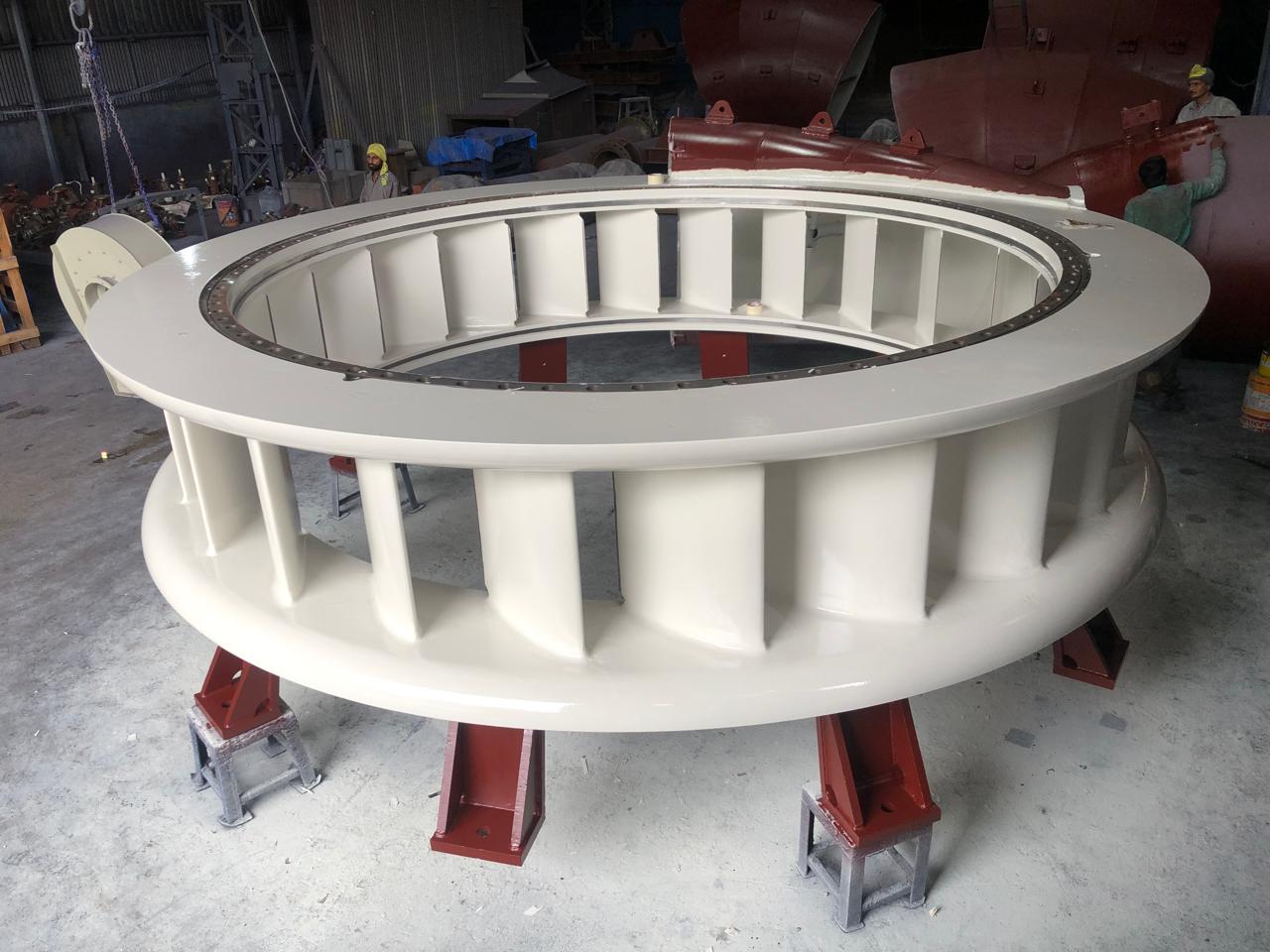

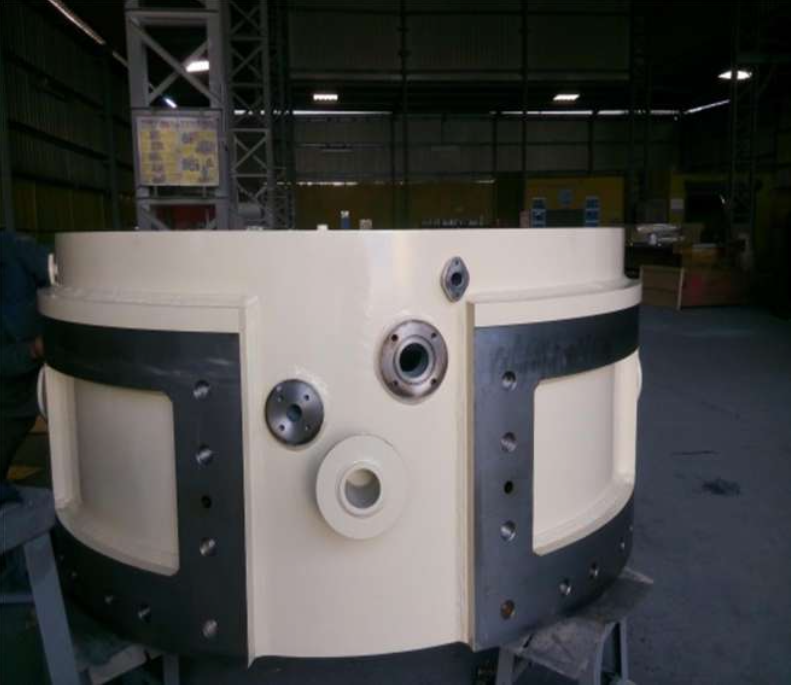

Regulating ring for industrial applications

Pulper vat for chemical processing

Condensate Pump Barrels

Blast booth for surface treatment

Defence Pressure Vessels

Engine Base-Frame

Base frame for large-scale equipment

Duplex Stainless Steel Equipment for Blasting and Painting

Bombshells with phosphating treatment

Bombshells for defense applications

Additional bombshells for military use

Defence Bomb Shell Process Cycle

Coal pulverizer component for energy sector

RPH pumps for industrial fluid management

Stator rotor assembly for electrical machinery

Stator frame for electrical applications

Stator component for power generation

Rotor Hub

Rotor component for rotating machinery

MRSAM missile component for defense systems

Oil Pan Assembly

SPECIAL PROJECT - Jumbo Incinerator Chamber & Burner

We have successfully completed a Jumbo Incinerator Chamber & Burner, Surface Preparation and multi-colour coat painting process, comprising of stringent Quality and Third Party Inspection criteria at our Talawade facility for the customer JOHN ZINK (End User - State Oil Company Of Azerbaijan Republic).

The Job requirements were Grit Blasting to SA 3 surface profile, and application of subsequent 4 coat paint system. The main Chamber was comprised to be painted with technologically advanced, which had critical application parameters, "temperature indicative Thermosensitive Paint (i.e. the paint which changes its colour from Green to Blue at 120 degrees and again from Blue to White at 230 degree Celsius.). The said paint is a specially designed imported paint with a cost of Rs 8600/ltr.

Also the Job was a very complex structure with 15 mtr length, 4 mtr Diameter, and single piece weight of 23 Tons.